#Keensert tap drill chart free

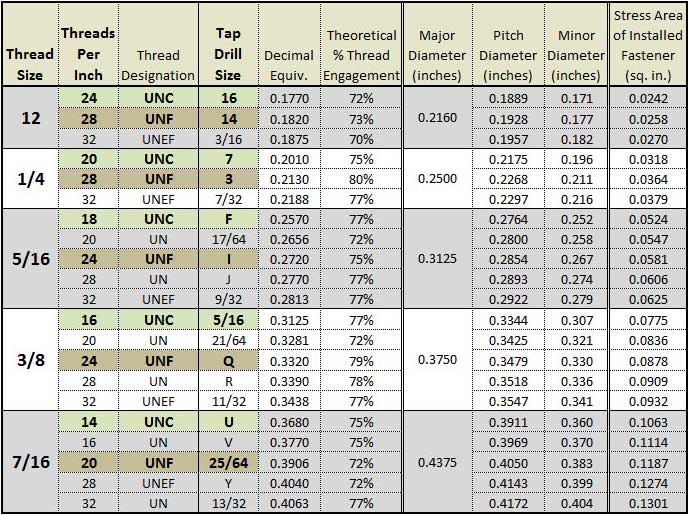

clean the hole so that it is free of chips in preparation for installation of the insert. Tap the insert installation threads in the housing using the recommended standard tap size.Īfter the hole is drilled, chamfered, and tapped.

In addition to being a cosmetic feature, the chamfered surface also helps to control the depth of the insert during installation.

The locking keys are mounted in dove-tail groove features cut into the insert body.ĭuring the last step of the installation, the keys are driven deeper into the dovetail slots to effectively lock the insert to the workpiece housing.The insert is provided with keys that lock the insert to the workpiece during installation.Īs supplied, the locking keys are initially located in the extended position as shown here.A Keensert is a solid threaded bushing-style insert that is available in standard dimension metric and inch sizes.In addition to thread repair applications, Keenserts are also sometimes used in new part manufacture to help provide thread durability to a softer base material. Inserts are able to be installed in a variety of housing materials including aluminum, steel, cast iron, and plastics.ĭifferent insert wall thickness configurations are available to suit a variety of application requirements. Once installed, there is a high resistance to insert pullout or torque out. The insert solid body and the use of standardized threads makes it difficult to accidentally cross-thread the insert during installation. Inserts are easily installed and removed using standard tooling. Some of the features and benefits of Keensert inserts include. A Keensert is a solid-body insert that is often the first choice in demanding thread repair applications.

0 kommentar(er)

0 kommentar(er)